Pipes & Tubes

|

Stainless Steel Seamless PIpe / Tube with Random Length 1.4541, AISI321, TP321, TP321H, F321, 08X18H10T, 12X18H10T, TP304H, TP310H, TP316H, TP321H, TP347H |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

HOLLOW BAR TP304/304L/304N/304H, TP310S/310H , TP316/316L Click Here

SEAMLESS STAINLESS STEEL PIPE SIZES: 1/8"NB - 24 "NB GRADES: TP304/304L/304N/304H, TP310S/310H , TP316/316L/316Ti/TP316H/316H/316LN, TP317/317L, TP317LN, TP321/321H, TP347/347H. Seamless stainless steel pipe is fully softened & descaled. In 5-7 metre random lengths. Tolerances & testing to ASTM A 312/ASME SA312-A530. Conforming to NACE Standard MR-01-75(Latest Revision) Certificate to DIN 50049-3.1.B./EN 10 204-3.1.B. SEAMLESS AND WELDED DUPLEX PIPE/SEAMLESS SUPER DUPLEX PIPE SIZES: 1/2"NB - 8"NB (Seamless Duplex/Super Duplex) SIZES: 6"NB - 24 "NB (Welded Duplex) Duplex Grade. Seamless Ferritic/Austenitic Stainless Steel Pipe to ASTM A790 UNS S31803 (Duplex) UNS S32760 (Super Duplex) and ASTM A928 UNS S31803 (Welded Duplex), . Cold/Hot finished, solution annealed & descaled in random lengths 5-7.5 metres. Conforming to NACE Standard MR-0175(Latest Revision) OTHER GRADES DIN17456 DIN 17458 EN 10216-5 TC 1/2 1.4301, 1.4307, 1.4404, Click Here

DIN17456 DIN 17458 EN 10216-5 TC 1/2 1.4301, 1.4307, 1.4404, Stainless Steel Seamless Pipe, cold drawing and rolling

Grade 304 / 304L / 304H DIN17456 DIN 17458 EN 10216-5 TC 1/2 Stainless Steel Seamless Pipe DIN17456 DIN 17458 EN 10216-5 TC 1/2 1.4301, 1.4307, 1.4404, Stainless Steel Seamless Pipe

Application:

Chemical Composition:

Mechanical Properties:

Grade specifications:for 304 grade stainless steel

Size Range:

Final Finishing: Solution Annealed & Pickled | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Seamless Duplex Stainless Steel Pipe ASTM A790 S31803 (2205 / 1.4462), UNS S32750(1.4410) UNS32304, UNS32760. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Seamless Duplex Stainless Steel Pipes EN 10216-5 1.4462 / 1.4410, UNS32760 Click Here

Seamless Duplex Stainless Steel Pipes EN 10216-5 1.4462 / 1.4410, UNS32760(1.4501) Standards: ASTM/ASME A789/SA789, A790/SA790,A450,A530 Material: UNS S31803(Cr22Ni5Mo3/1.4462)/2205,UNS S32750(1.4410),UNS S31500(Cr18NiMo3Si2), UNS32760(1.4501)

Chemical Composition

Physical Properties

Duplex Stainless Steel Pipe Application: Chemical processing, Transport and Storage. Oil and gas exploration and offshore rigs. Oil and gas refining. Marine environments. Pollution control equipment. Pulp and paper manufacturing Chemical process Plant Seamless Duplex Stainless Steel Pipe ASTM A789 S32760,S32750, 32550, Click Here

Seamless Duplex Stainless Steel Pipe ASTM A789 S32760, ASTM / ASME A789 / SA789 Standards: ASTM/ASME A789/SA789, A790/SA790,A450,A530 Material: UNS S31803(Cr22Ni5Mo3/1.4462)/2205,UNS S32750(1.4410),UNS S31500(Cr18NiMo3Si2), UNS32760(1.4501)

Chemical Composition

Physical Properties

Duplex Stainless Steel Pipe Application: Chemical processing, Transport and Storage. Oil and gas exploration and offshore rigs. Oil and gas refining. Marine environments. Pollution control equipment. Pulp and paper manufacturing Chemical process Plant

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stainless Steel Welded Pipe ASTM A269 ASTM A312 ASTM A358 ASTM ,A688 ASTM A778 EN10217-7 ,DIN17457 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Welded Pipes DIN 17457 1.4301 / 1.4307 / 1.4401 Click Here

Stainless Steel Welded Pipes DIN 17457 1.4301 / 1.4307 / 1.4401 / 1.4404 EN 10204-3.1B

Standard Specification: ASTM A249 / A249M - 10a Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes ASTM A269 - 10:Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service ASTM A312 / A312M - 12:Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes ASTM A358/A358M-08a:Standard Specification for Electric-Fusion-Welded Austenitic ASTM A778 - 01(2009)e1:Standard Specification for Welded, Unannealed Austenitic Stainless Steel Tubular Products ASTM A789 / A789M - 10a:Standard Specification for Seamless and Welded Ferritic Austenitic Stainless Steel Tubing for General Service ASTM A790 / A790M - 11:Standard Specification for Seamless and Welded Ferritic Austenitic Stainless Steel Pipe Others like BS, JIS , DIN , EN , GOST standard we all can supply .

Material Grade:

Size Range:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super Duplex Welded Pipe : A790 S32304, S32750, S32760 Click Here

Stainless Steel U Bend Tube ,ASTM A213, ASME SA213, ASTM A249 ,ASME SA249, ASTM A789, EN10216-5 A106/A1016M Super Duplex Welded Pipe : A790 S32304, S32750, S32760 , S31500, 6MO Material Grade:

Size Range:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stainless Steel U Bend Tube ASTM A213, ASME SA213, ASTM A249 ,ASME SA249, ASTM A789, EN10216-5 A106/A1016M |

||||||||||||

Stainless Steel U Bend Tube ,ASTM A213, ASME SA213, ASTM A249 Click Here

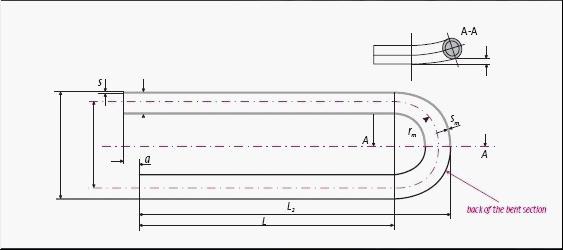

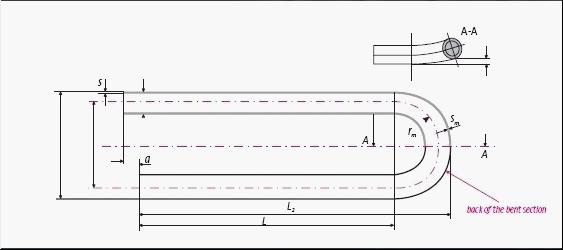

U-Bend Tube are widely used in Heat Exchanger Systems. Heat-Exchanger Equipment on the basis of Seamless Stainless U-Tubes and Welded Stainless U bend Tube is essential in strategically important and critical felds---Nuclear And Petrochemical Machine Building. XINGZHOU Group Start to Produce U Bending Tube Since 2006,Up to now already supply more than 30000 tons Stainless Steel U Bend Tube to 35 countries.

The U-Bend Tube Comply With The Following Standards: 1. ASTM A688/ASME SA688 2. ASTM A803/ASME SA803 3. ASTM A556/ASME SA556

Steel Grade

Tube Of Other Alloys And Steel Grades Can Be Produced Upon Agreement. Straight Tubes Standard Specification For Bending: ASME SA 213; ASME SB 163; ASME A789, ASME SA268, ASME SA269, etc. Marking: Before Bending By Marking Machine All Over The Tube Length (Bent Section After Heat Treatment Without Marking) Note: Marking is also possible After Bending On The Straight Parts Of U-Bending Tube.

U-Bend Tubes: -TEMA RCB 2.31 Standard Of The Tubular Exchanger Manufacturers Association (9th Edition). -ASTM A688/ASME SA688 Standard Specification For Welded Tubes Of Austenitic Corrosion Resistant Steel Grade Designed For Feed Water Boilers. -ASTM B163/ASME SA163 Standard Techinical Requirements For Tubes Of Nickel And Nickel Alloy For Condensers And Heat Exchangers.

-Customer Specifications.

Bending Radius: From 1.5*OD(Outside Diameter) To 1500mm When Ordering Tubes With Radius less or equal to 1.5*OD, It Is Necessary To Agree Precision Of Geometrics. Straight Tubes Maximum Length:(Before Bending): 35000 mm. Leg Length: Min 1 Meter, Max. 16500 mm (For Max R=1500mm) Note: Other Size Are Available Upon Agreement. Heat Treatment: Stress Relieved After U-Bending (Bending Area Plus 300MM For Each Leg). Hydrostatic Test After U Bending: Maximum Test Pressure 600 Bar, Soaking 10 Sec. With Dematerialized Water. Compressed Air Cleaning After Hydro-Test. Packaging: In Strong Transport-Worthy Pre-fumigated wooden boxes of corresponding dimensions for each tube Length, Radius, Diameter, According To PO requirements as well as wrapped In polyethylene films With soft plastic caps on both end of Tube.

|

|||||||||||||

Stainless Steel U Bend Tube, Eddy Current Test, Hydrostatic Test Click Here

Stainless Steel U Bend Tube, Eddy Current Test, Hydrostatic Test , Ultrasonic Test , Air Pressure Test , A213/SA213 Stainless Steel U Bend Tube ASME A789, ASME SA213 TP317 / TP317L / TP321 / TP321H

U-Bend Tube are widely used in Heat Exchanger Systems. Heat-Exchanger Equipment on the basis of Seamless Stainless U-Tubes and Welded Stainless U bend Tube is essential in strategically important and critical felds---Nuclear And Petrochemical Machine Building. Xinzhou Group Start to Produce U Bending Tube Since 2006, Up to now already supply more than 30000 tons Stainless Steel U Bend Tube to 35 countries.

The U-Bend Tube Comply With The Following Standards: 1. ASTM A688/ASME SA688 2. ASTM A803/ASME SA803 3. ASTM A556/ASME SA556

Steel Grade:

Tube Of Other Alloys And Steel Grades Can Be Produced Upon Agreement

Technical Requirements:

Straight Tubes Standard Specification For Bending: ASME SA 213; ASME SB 163; ASME A789, ASME SA268, ASME SA269, etc. Marking: Before Bending By Marking Machine All Over The Tube Length (Bent Section After Heat Treatment Without Marking) Note: Marking is also possible After Bending On The Straight Parts Of U-Bending Tube.

U-Bend Tubes: -TEMA RCB 2.31 Standard Of The Tubular Exchanger Manufacturers Association (9th Edition). -ASTM A688/ASME SA688 Standard Specification For Welded Tubes Of Austenitic Corrosion Resistant Steel Grade Designed For Feed Water Boilers. -ASTM B163/ASME SA163 Standard Techinical Requirements For Tubes Of Nickel And Nickel Alloy For Condensers And Heat Exchangers.

-Customer Specifications.

Bending Radius: From 1.5*OD(Outside Diameter) To 1500mm When Ordering Tubes With Radius less or equal to 1.5*OD, It Is Necessary To Agree Precision Of Geometrics. Straight Tubes Maximum Length:(Before Bending): 35000 mm. Leg Length: Min 1 Meter, Max. 16500 mm (For Max R=1500mm) Note: Other Size Are Available Upon Agreement. Heat Treatment: Stress Relieved After U-Bending (Bending Area Plus 300MM For Each Leg). Hydrostatic Test After U Bending: Maximum Test Pressure 600 Bar, Soaking 10 Sec. With Dematerialized Water. Compressed Air Cleaning After Hydro-Test. Packaging: In Strong Transport-Worthy Pre-fumigated wooden boxes of corresponding dimensions for each tube Length, Radius, Diameter, According To PO requirements as well as wrapped In polyethylene films With soft plastic caps on both end of Tube.

Features :

|

|||||||||||||